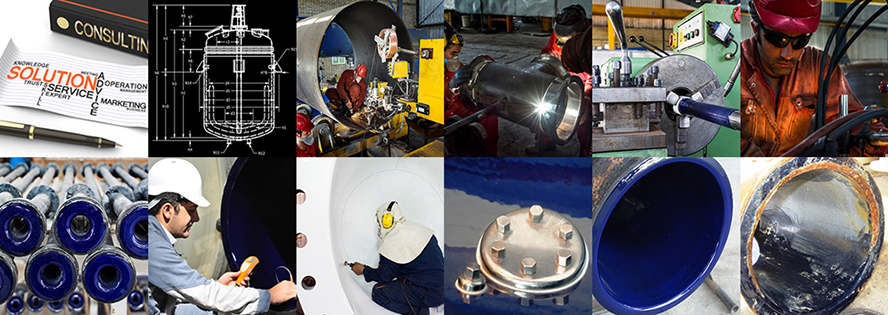

About Glass (Glass Lining)

Due to its crystalline structure and intrinsic nature, glass is one of the most resistant materials against a wide range of corrosive environments. Its chemical resistance is comparable to that of special alloys such as Hastelloy, titanium, and similar materials, which are significantly more expensive than glass.

Therefore, using these materials as coatings is highly attractive from an economic perspective. Glass lining enables ordinary carbon steel to achieve corrosion resistance comparable to costly alloys like Hastelloy and titanium. At the same time, limitations associated with glass—such as formability and mechanical strength in equipment manufacturing—are overcome by using steel as the structural material. In essence, glass lining combines the excellent chemical resistance of glass with the strength, formability, and cost-effectiveness of carbon steel.

Glass-lined equipment plays a critical and strategic role in the chemical industry, as many chemical reactions require equipment with high corrosion resistance. Meanwhile, the use of expensive materials and alloys is often not economically justifiable depending on the product being manufactured. As a result, in many cases, glass-lined equipment represents the only viable solution for production.

Equipment commonly manufactured with glass lining includes chemical reactors, storage tanks, pressure vessels, chemical columns, dryers, various types of heat exchangers, pipes and fittings, valves, and more. In addition, auxiliary reactor components such as agitators, baffles, and similar parts can also be produced with glass lining.

Advantages of Glass Lining

- High corrosion resistance in most acidic environments and organic solvents

- Suitable temperature resistance (−25 to 220 °C)

- Extremely low permeability compared to other coatings

- Very smooth surface with excellent cleanability (CIP)

- Hygienic properties compliant with GMP requirements

- Ability to withstand high pressure

- Non-catalytic behavior

- High abrasion resistance

- Favorable heat transfer compared to other coating systems