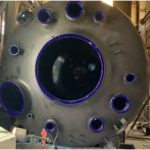

Glass-Lined Reactors

General Definition and Application

Glass-lined reactors are considered the optimal solution for carrying out sensitive and corrosive chemical reactions. The glass lining provides high chemical resistance and a non-reactive surface suitable for demanding process conditions.

Design Standards and Engineering Criteria

Glass-lined reactors are designed and manufactured in accordance with ASME standards based on the required operating pressure and temperature. Reactor dimensions, including diameter-to-height ratios for each capacity, are determined in accordance with DIN standards. Manufacturing reactors in compliance with these standards leads to improved process efficiency and facilitates easier operation and maintenance.

According to DIN standards, three types of glass-lined reactors are defined: CE, BE, and AE.

Glass-Lined Reactor with Fixed Upper Head

Design Characteristics and Capacity Range

This type of glass-lined reactor can be designed and manufactured for capacities up to 6,300 liters.

Agitation System

The installation of an anchor-type agitator is possible in this reactor design.

Structural Configuration

In this configuration, the upper head of the reactor is manufactured separately from the vessel body and is connected to the vessel using clamps and flanges.

Glass-Lined Reactor with Fixed Upper Head

Operating Conditions

This type of reactor is generally more suitable for operation under high-pressure conditions.

Nozzles and Access

In addition to process nozzles, this reactor configuration includes only one access opening (manhole).

Agitation System

Only turbine-type pitch blade agitators with a locking mechanism can be used in this reactor design.

Glass-Lined Reactor with Fixed Upper Head

Structural Features

In addition to process nozzles and a manhole, this reactor type includes a dedicated agitator entry nozzle.

Agitation Limitations

Installation of an anchor-type agitator is not possible in this configuration.

Pressure Suitability

Due to the reduced sealing surface area, this type of reactor is more suitable for high-pressure operation.

Capacity Range

The manufacturable capacity range for this reactor type is from 1,600 liters to 33,000 liters.