Advantages of Fluoropolymers

- - High chemical resistance (pH 0–14)

- - High thermal resistance

- - Excellent corrosion resistance

- - Mechanical resistance to impact and abrasion

- - Non-permeable

- - Suitable for pressure and vacuum conditions

Fluoropolymer coatings

Fluoropolymers are a class of olefins. Olefins are thermoplastic materials in which all or part of the hydrogen atoms are replaced with fluorine. In polymers such as PFA and PTFE, this substitution is complete, while in polymers such as ECTFE, the substitution is partial. These polymers exhibit very high resistance to a wide range of corrosive environments at elevated temperatures. For this reason, they are widely used in the chemical industry for lining the internal surfaces of equipment such as tanks, towers, pipes and fittings, and valves that are exposed to corrosive substances. Among non-metallic coatings, these linings provide the highest levels of chemical and thermal resistance.

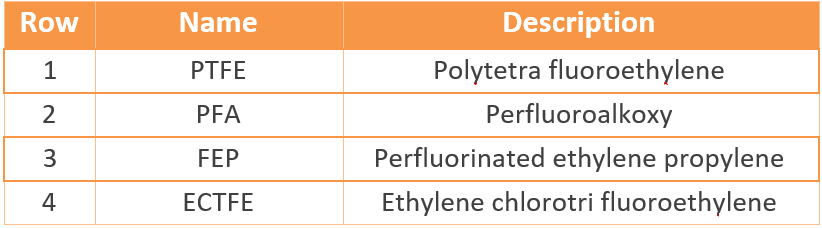

Fluoropolymers are available in various types, which are referenced in the table below. Due to the differing properties and behavior of these polymers, their selection for lining applications must be carried out by relevant specialists based on the operating chemical conditions as well as the type of equipment.

Characteristics of Fluoropolymer Linings

- • Chemical corrosion resistance (pH 0–14) and suitable thermal resistance

- • Chemical corrosion resistance (pH 0–14) and suitable thermal resistance

- • Suitable resistance to impact and shock

- • Proper adhesion to metal surfaces or base materials

- • Variety of coating application methods depending on polymer type

- • Capability for operation in equipment under pressure or vacuum

- • High cleanability