About Glass Lining

About Glass Lining

What Is Glass Lining?

Glass lining is an industrial process in which a chemically resistant glass layer is applied to the internal surface of metal equipment using a powder coating method. After application, the component is placed inside a furnace, where high-temperature firing causes the glass layer to permanently and uniformly fuse with the base metal through thermal bonding.

The thickness of the glass lining varies depending on application type and process conditions. However, a thickness of approximately 2 millimeters is typically used for most industrial equipment, including glass-lined reactors, glass-lined vessels, and glass-lined heat exchangers.

Chemical Resistance and Technical Advantages

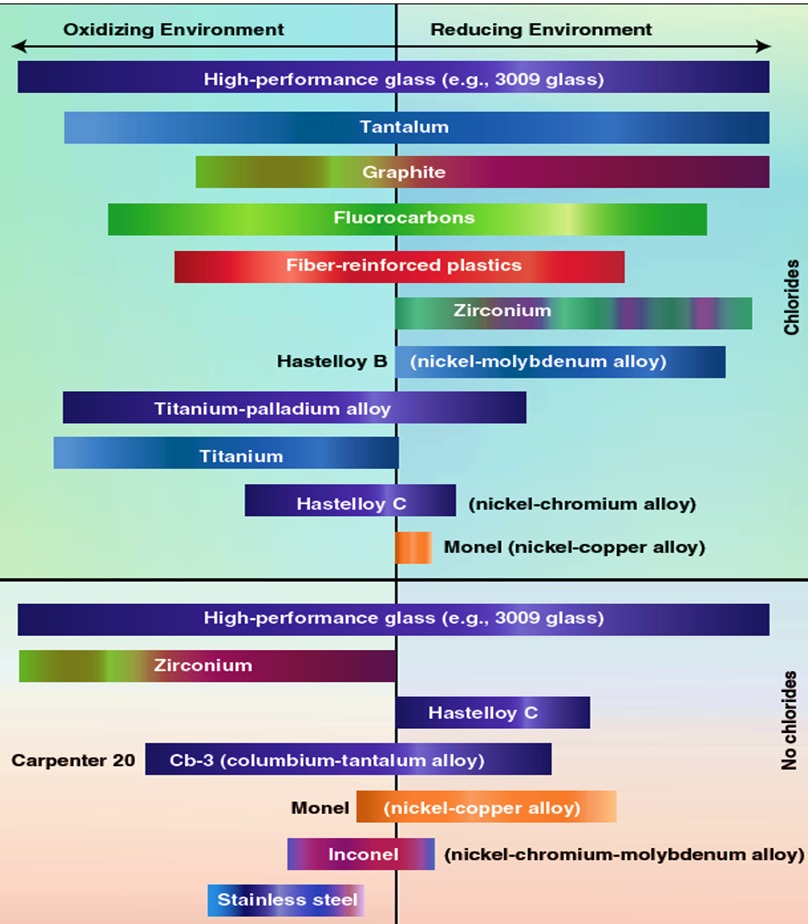

In terms of corrosion resistance, glass lining is comparable to specialty metals such as tantalum, titanium, and zirconium. However, the manufacturing cost of equipment made from these metals is several times higher than that of glass-lined equipment.

Glass lining exhibits high resistance to a wide range of acidic and alkaline substances and can be used in both oxidizing and reducing environments without performance degradation. These characteristics make glass lining a reliable and cost-effective solution for chemical, pharmaceutical, and petrochemical industries that require high chemical resistance, long service life, and non-reactive surfaces.

Glass-Lined Equipment Manufacturing Process

Overview of the Manufacturing Process

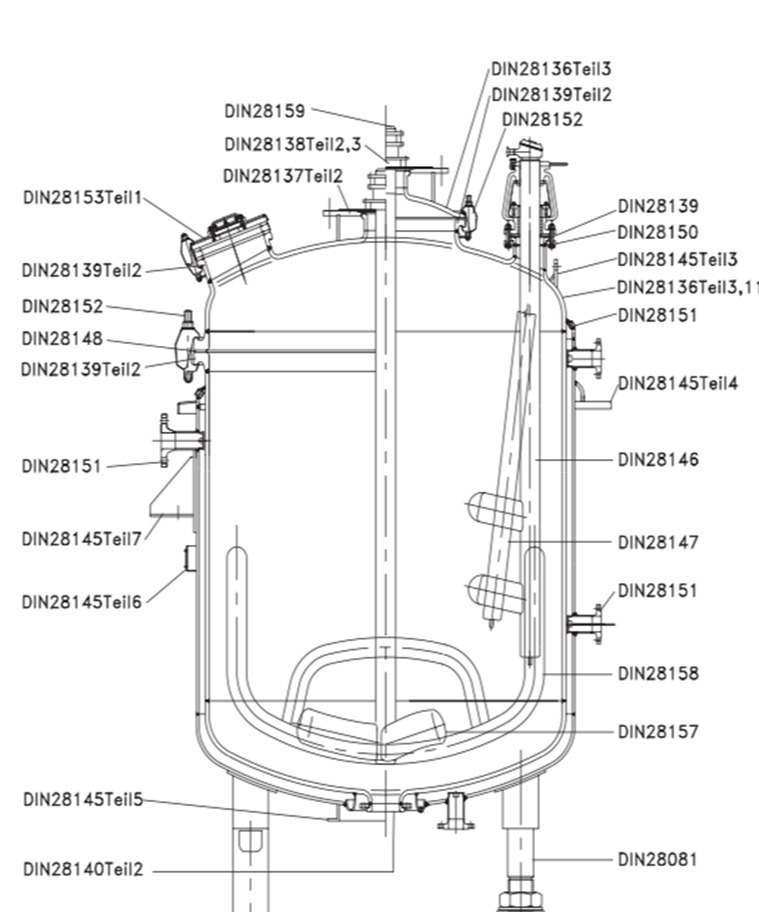

The production of glass-lined equipment is a multi-stage process that includes engineering design, raw material selection, metal fabrication, glass lining application, assembly, quality control, and final delivery. Strict compliance with international standards such as DIN 28136 and ASME Section VIII throughout all stages ensures equipment quality, durability, and operational safety in chemical, pharmaceutical, and petrochemical applications.

1. Design and Engineering

The design and engineering of glass-lined equipment are carried out in accordance with DIN 28136, which defines detailed specifications for dimensions, tolerances, nozzle locations and sizes, manholes, agitators, flanges, and fastening systems. Adherence to this standard directly affects reactor performance, flow turbulence, operational efficiency, and equipment service life.

Pressure design is performed in accordance with ASME Section VIII. Application of this standard ensures long-term safety, stable performance, and reliable operation of pressure-bearing equipment.

2.Procurement of Raw Materials

The quality of raw materials plays a decisive role in the performance and durability of glass-lined equipment. Base metals include A516 Gr.65 steel plates, A106 standard pipes, and CK45 shafts.

Glass frit is another critical raw material that directly affects glass lining quality. Frit is a compound of mineral and metallic oxides, each contributing specific chemical and mechanical properties to the glass, including thermal expansion coefficient, corrosion resistance, and mechanical strength.

Auxiliary components such as mechanical seals, bearings, gearboxes, and electric motors also have a direct impact on the reliability and continuous operation of the production line.

3. Metal Fabrication

More than 50% of glass-lined equipment manufacturing technology is related to metal fabrication. If standard metalworking processes are not properly followed, achieving high-quality glass lining is not possible.

Key stages in metal fabrication include:

Weld Radiography

Radiographic inspection of weld seams to verify structural integrity and detect internal defects.

Nozzle Forging

Forging of nozzles to achieve the required mechanical strength and dimensional accuracy.

Standard Corner Curvature

Creation of standard curved corners to ensure uniform stress distribution and proper glass adhesion.

Stress Relief

Heat treatment to reduce residual stresses generated during fabrication and welding.

Degassing and Annealing

Controlled thermal processes to remove trapped gases and stabilize the metal structure.

Surface Treatment

Preparation and finishing of metal surfaces to ensure optimal bonding with the glass lining.

4. Glass Lining – Frit Producing & Enameling

Glass frit is a compound of metallic and mineral oxides, with each component serving a defined function such as controlling thermal expansion, corrosion resistance, color, and mechanical strength. The frit production process includes melting the compound at approximately 3000°C, rapid cooling (quenching), and milling.

Types of Glass Frit Used (Glass Types)

Each frit type is selected based on the specific application of the equipment:

General industrial blue glass (General-AZR Glass)

High-purity pharmaceutical glass (PH-AZR Glass)

White corrosion-resistant glass (W-AZR Glass)

5. Enameling Process

The enameling process consists of multiple glass layers. Each layer must have an approximate thickness of 250 microns, resulting in a final glass lining thickness of up to 2200 microns.

At each stage, precise heat treatment is applied to eliminate trapped gases and bubbles, creating a uniform and long-lasting glass lining.

This process requires a strong and stable metal body capable of maintaining its mechanical properties under high temperatures. This stage of production is a major factor in determining both the final quality and cost of the equipment.

6. Assembling

During this stage, main components such as nozzles, manholes, agitators, and heating and cooling systems are assembled with high precision. Accurate assembly improves overall equipment performance and reduces the risk of leakage during operation.

7. Quality Control

All manufactured equipment undergoes rigorous testing, including spark testing, glass thickness measurement, pressure testing, and visual inspection, to ensure the absence of defects and full compliance with technical requirements.

9. Client Delivery and Shipping

After final approval, the equipment is prepared for shipment using appropriate industrial packaging. Technical documentation and quality control certificates are provided with the equipment for both domestic and international clients.