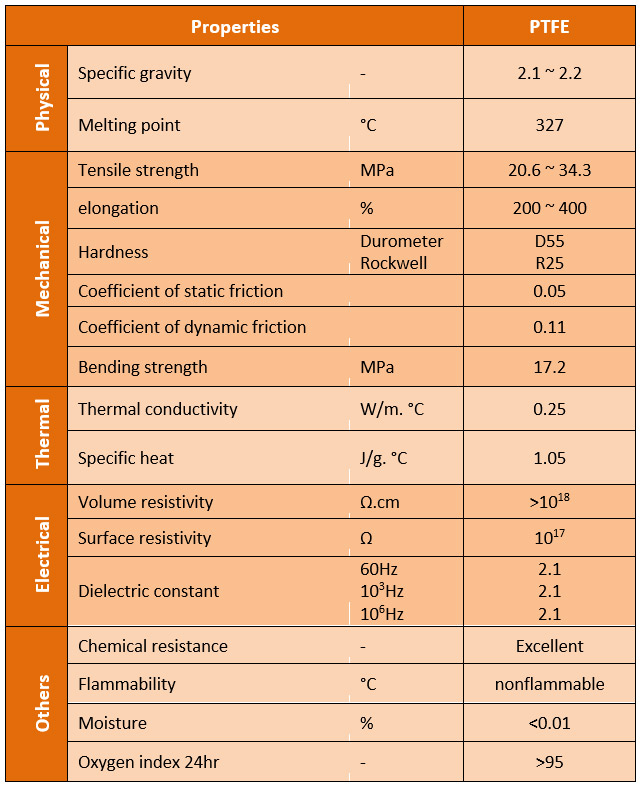

About PTFE

PTFE (Polytetrafluoroethylene) is a non-stick fluoropolymer coating with the highest operating temperature among fluoropolymers. It features an extremely low coefficient of friction, moderate wear resistance, and excellent chemical resistance. This coating is commonly used where a dry lubricant, a low-friction surface, or corrosion resistance is required.

The PTFE coating process provides exceptional release properties and can withstand continuous service temperatures of up to 600°F (316°C)—higher than any other fluoropolymer. The coating is typically applied at a thickness of 1 to 5 mils.

Benefits of PTFE-Coated Fasteners:

- Corrosion resistance

- Chemical resistance

- Easy assembly and disassembly

- Low coefficient of friction

- High temperature resistance

Industrial PTFE coatings can be applied to steel, alloy steels, brass, aluminum, and certain specialty materials such as Inconel. For proper adhesion, the substrate must be abraded to ensure a strong bond between the PTFE coating and the base material.